How much does an ultrapure water system cost?

Which type of water is best for my lab?

How much does a lab water system cost to maintain?

If you manage a laboratory, you want the full picture: what drives price, how to avoid hidden costs, and how to choose a system that won’t let you down test. This guide lays out the true cost of ownership, fit by application, and the pros/cons of each system type.

The quick overview (what you’re really paying for)

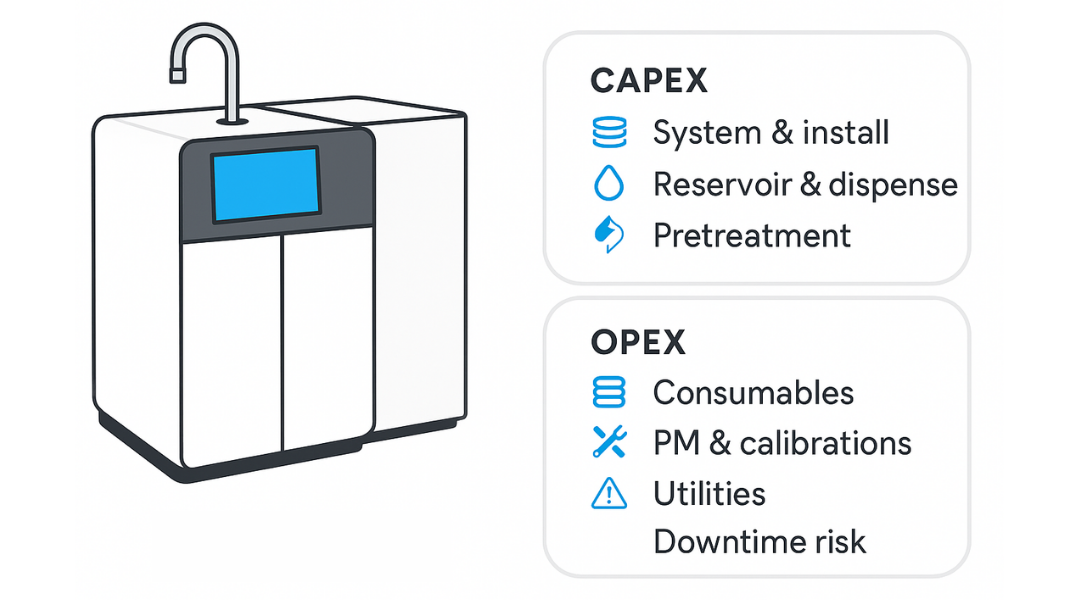

Up-front (CAPEX)

- System hardware (Type III RO / Type II polish / Type I ultrapure, or a combined bench-top)

- Installation & commissioning.

- Additional reservoirs & dispense hardware (remote taps, wall/bench kits).

Ongoing (OPEX)

- Consumables (pre-filters, DI/polish packs, UV lamp, final 0.22 µm)

- Preventive maintenance & calibrations (Carbon Pretreatment Unit, RO membrane, conductivity/resistivity, TOC)

- Utilities (water reject from RO, electricity)

- Downtime (the hidden one: delayed assays, staff time, off-site water purchases)

Purific Lab Water System Price Range

The below table is a range indicator of what a Purific system might cost to run over a 10-year period. Obviously, consumables cost is not included due to there being two main factors that are outside of our control.

- Feed water quality.

- Pure water usage.

Note: When estimating your consumable usage analyser companies will always give you maximum usage which in our experience can be anywhere up to 50% more than actual average usage. The best method to verify consumption is to measure actually usage over a 2 week period.

| Lucid 200 | Analytica 100 | Analytica 100 Pro | |

| System and Installation | $8,500 – $16,000 | $15,000 – $27,000 | $25,000 – $38,000 |

| Dual Redundancy | $3,500 | ||

| Preventative Maintenance (Annual) | $1,100 – $1,900 | $1,950 – $3,750 | $3,250 – $4,500 |

| Optional Complete Cover – Zero Call-out Fees (Annual) | $1,150 | $1,250 | $2,250 |

| Consumables (Cost per Liter) | $0.03 | $0.03 | $0.03 |

| Capital Outlay | $8,500 – $16,000 | $15,000 – $31,500 | $25,000 – $41,500 |

| 10 Year Maintenance Cost Projection | $11,000 – $30,500 | $25,000 – $50,000 | $32,500 – $67,000 |

| Total Lifespan Cost Range (10 Years) ex. consumables | $19,500 – $46,500 | $40,000 – $77,000 | $57,500 – $108,500 |

Which “type” water do you actually need?

It is important to be aware there are more than 1 standard that can be applied when looking at laboratory grade water. Read https://purific.com/waterstandards/ to understand more about this topic. These include ASTM, ISO 3696:1987, and CLSI (formerly NCCLS).

Generally the following grades would be applicable but is it important to ensure that the quality water your laboratory specifies is fit for purpose.

- Type III (RO): Glassware rinse, autoclaves, feed to Type II/I.

- Type II (pure): General reagents, buffers, instruments not sensitive to organics.

- Type I (ultrapure): HPLC/LC-MS, molecular biology, cell culture, trace analysis; often with TOC monitoring, optional UF (endotoxin, RNase/DNase control), and final 0.22 µm.

Many labs run a stack (Type III → II → I) or a compact benchtop that takes RO/tap and outputs Type I on demand.

Factors to consider when trying to estimate what your lab water system will cost.

What really drives the price (and reliability)?

- Daily volume & peak draw (L/day, L/min) and whether you need a reservoir.

- Service & Support Is 24/7 Technical support a requirement i.e. does your laboratory support a hospital emergency department? What happens if you system breaks down during the night?

- Feed water quality (hardness, silica, chlorine/chloramine, organics/TOC) → pretreatment spec.

- Purity targets (Type, TOC, endotoxin, RNase/DNase, particles).

- Ergonomics & footprint (bench, wall, under-bench; reach height; noise).

- Compliance (IQ/OQ, calibration certificates, audit trails/logs).

- Consumables cadence (change intervals at your usage).

Pros & cons by system approach

Ultrapure bench-top (Type II & I)

- Pros: Small footprint, point-of-use purity, quick-change consumables, ideal for sensitive assays.

- Cons: Needs suitable feed (RO), reservoir planning matters for peak flows if feed supply has limited capacity.

Wall Mounted (Type II/SRW)

- Pros: No lost bench space, small footprint, point-of-use purity, ideal for mid size laboratories needing larger volumes of water but not type 1 grade, standard tap water is suitable feed quality in most cases, ideal for clinical analyser supply.

- Cons: Cannot provide ASTM Type 1 grade water, must have sufficient wall space available in laboratory.

Modular RO + Type II + Type I stack

- Pros: Scalable; robust for higher daily volumes, clear staging of consumables,

- Cons: More space, more plumbing, plan maintenance windows across modules.

Central system feeding multiple taps

- Pros: Best for many users/rooms, uniform quality, fewer individual units to service

- Cons: Higher CAPEX, harder to maintain high quality due to the number of instances for contamination. i.e every tap, loop join provides opportunity for contamination, distribution loop design/validations, Point of use polishers still required for quality assurance.

The maintenance picture (how to avoid “death by downtime”)

- User-Serviceable Can your system be maintained by the staff to ensure your laboratory is not beholden to the water system supplier i.e. minor issues can be self-diagnosed and repaired by staff or via the help of a phone call.

- Design for service: quick-change cartridges, clean handling, and service level provided by vendor.

- Plan intervals: establish change triggers by throughput or quality thresholds (resistivity, TOC)

- Keep critical spares: 0.22 µm final filters, absolute filters, UV lamp; log lamp hours/TOC alarms.

- Calibrate with proof: resistivity/temperature, TOC verification; keep certificates with PM reports

- Document: PM checklist, part numbers, and stock levels so purchasing isn’t scrambling

Hidden costs to surface (before you sign)

- Under-spec’d pretreatment → Chlorine breakthrough, sediment blockages.

- Peak-flow bottlenecks → Instrument timeouts causing run delays.

- Unclear consumables matrix → Year-2 surprises i.e. EDI failure can be very costly.

- Long lead times → Inventory carrying costs or downtime risk, supplier not holding spare parts, or system becomes obsolete just after purchase.